Bin Activator Types & Accessories

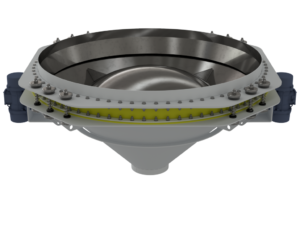

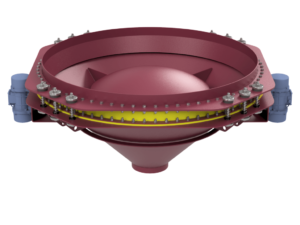

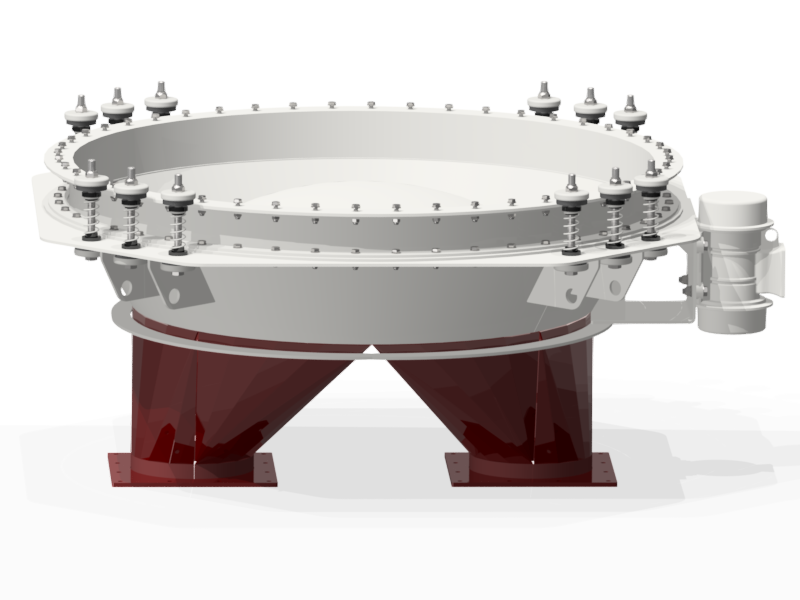

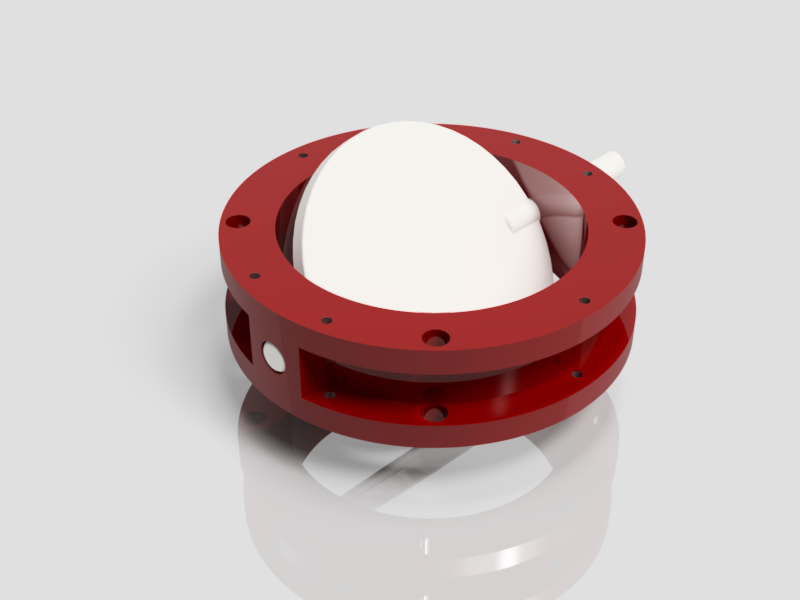

Polimak standard bin activators are industrially engineered in seven different models. They are used in several industrial applications to facilitate the smooth flow of dry bulk materials from upstream vessels such as silos or hoppers. Our bin activators ensure optimal feeding of bulk solids, thus preventing bridging, ratholing, segregation or incomplete emptying. These equipment have special design features that ensure safe operation in the long run.

Polimak standard bin activators are industrially engineered in seven different models. They are used in several industrial applications to facilitate the smooth flow of dry bulk materials from upstream vessels such as silos or hoppers. Our bin activators ensure optimal feeding of bulk solids, thus preventing bridging, ratholing, segregation or incomplete emptying. These equipment have special design features that ensure safe operation in the long run.

Features

- Construction Material: ST37 Carbon Steel.

- 1 or 2 electric motors (vibrators).

- 4 to 16 suspensions.

- Single outlet.

- Flexible connector sleeve.

- Primary baffle plate.

- Inlet skirt.

- Multiple outlets (optional).

- Secondary baffle plate (optional).

Benefits

- Ensures the uniform mass flow of the product.

- Prevents ratholing, segregation and incomplete emptying of the discharged material.

- Avoids bridging/arching in silos or hoppers.

- No material spillage or loss of product.

- Handles product gently without damaging it.

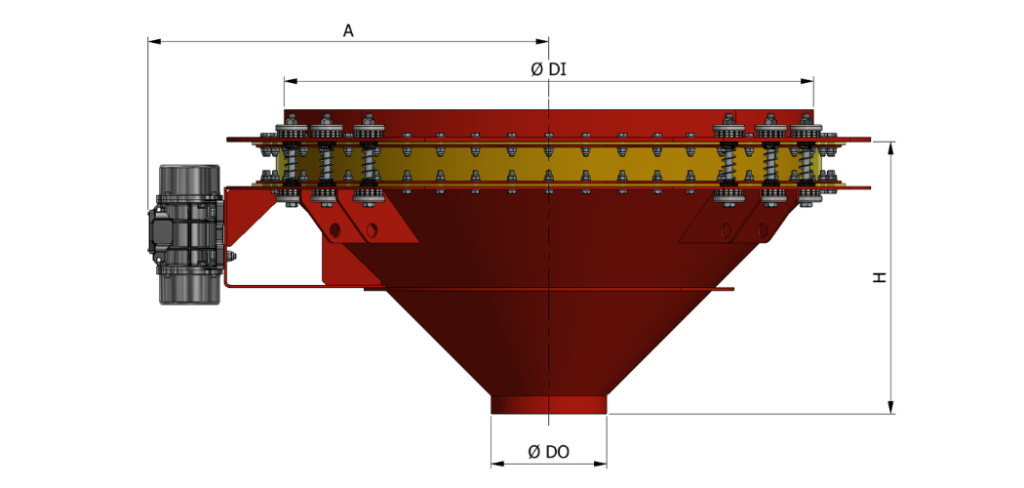

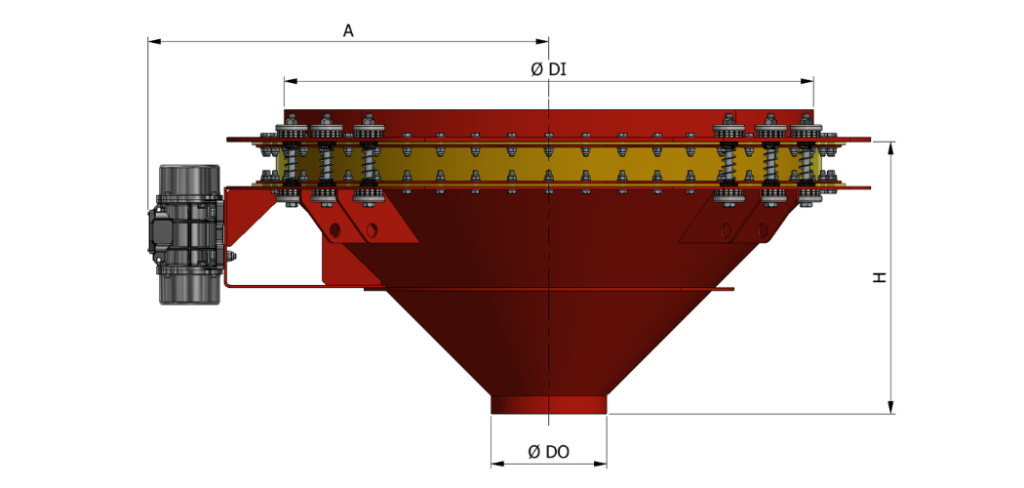

Bin Activator Dimensions Table

| MODEL | A(mm) | ØDI (mm) | ØDO (mm) | H (mm) | No. of Suspensions | No. of Motors |

| PTK600 | 500 | 580 | 168 | 400 | 4 | 1 |

| PTK900 | 685 | 880 | 219 | 520 | 4 | 1 |

| PTK1500 | 1115 | 1480 | 323 | 760 | 12 | 1 |

| PTK1800 | 1190 | 1780 | 323 | 910 | 12 | 2 |

| PTK2350 | 1595 | 2330 | 406 | 1150 | 16 | 2 |

| PTK2500 | 1720 | 2480 | 406 | 1290 | 16 | 2 |

| PTK2600 | 1820 | 2580 | 406 | 1350 | 16 | 2 |

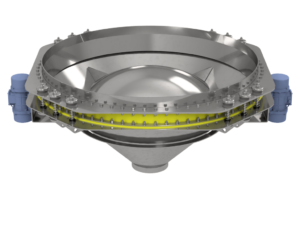

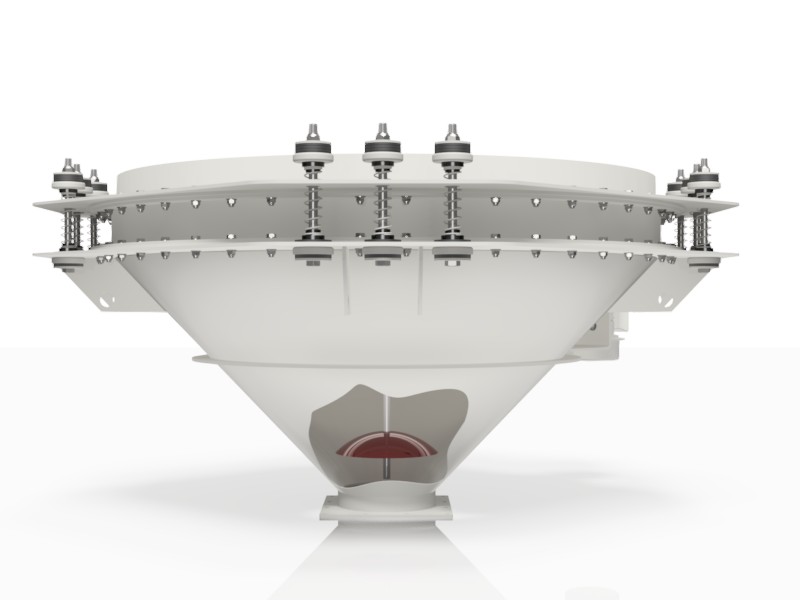

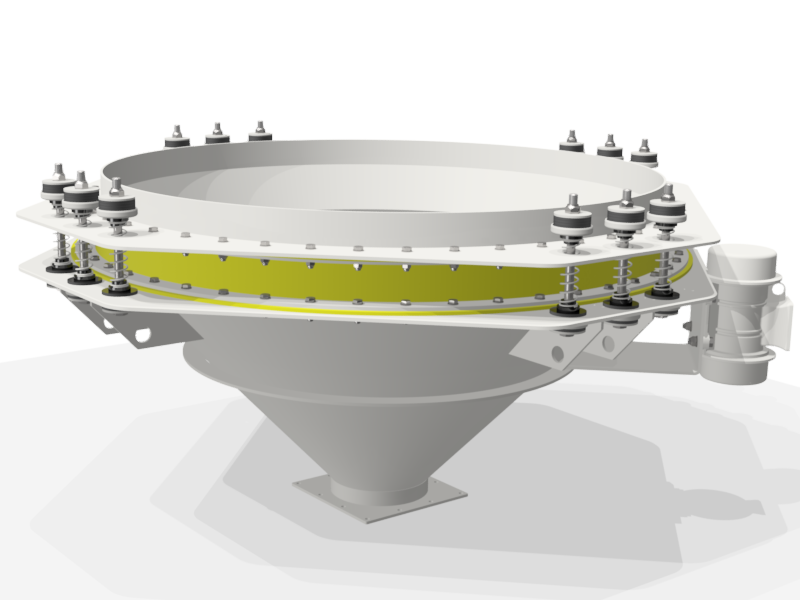

Polimak food-grade bin activators are specially engineered to meet the demands of the food industry. They can operate in applications that require minimum material residue and complete avoidance of contamination. With regard to quality, assurance, and reliability, our food-grade bin activators are the ideal option for uses that demand material discharge that is safe and consistent.

Polimak food-grade bin activators are specially engineered to meet the demands of the food industry. They can operate in applications that require minimum material residue and complete avoidance of contamination. With regard to quality, assurance, and reliability, our food-grade bin activators are the ideal option for uses that demand material discharge that is safe and consistent.

Our food-grade vibrating bin discharger types are manufactured with smooth edges, thus minimizing material residue and contamination. These bin dischargers are ideal for various applications in food processing because of their hygienic design and CE marking.

Features

- Construction Material: AISI304 Stainless Steel

- 1 or 2 electric motors (vibrators)

- Single outlet.

- 4 to 16 suspensions.

- Flexible connector sleeve

- Primary baffle plate

- Inlet skirt

- High-grade surface finishing

- Seamless activator cone

- ATEX certification for different zones (optional)

- Multiple outlets (optional)

- Secondary baffle plate (optional)

Benefits

- Minimum residue because of the design.

- Smooth and continuous material flow assurance.

- Bridging, ratholing and segregation prevention.

- Handle material gently with minimized particle damage.

- Prevention of material spillage thus reduced product loss.

- Downtime reduction, thereby promoting

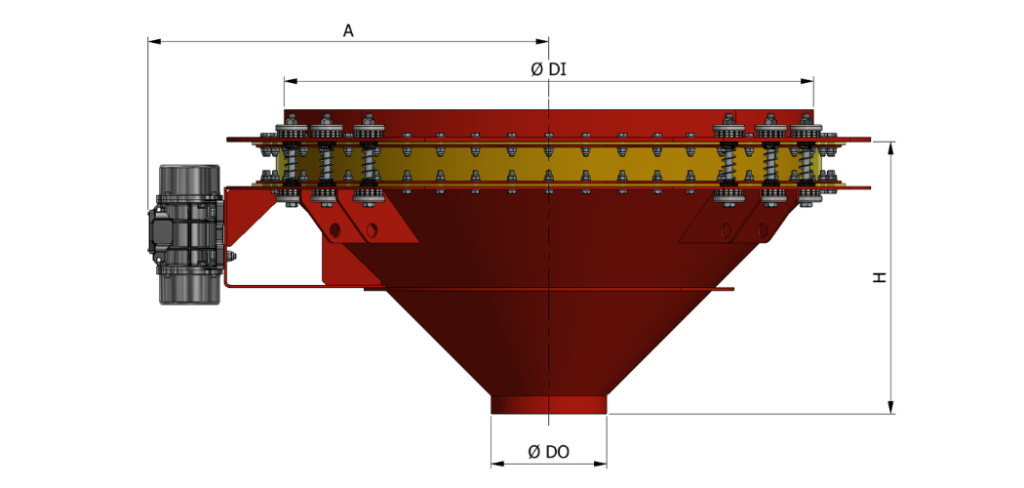

Bin Activator Dimensions Table

| MODEL | A(mm) | ØDI (mm) | ØDO (mm) | H (mm) | No. of Suspensions | No. of Motors |

| PTK600 | 500 | 580 | 168 | 400 | 4 | 1 |

| PTK900 | 685 | 880 | 219 | 520 | 4 | 1 |

| PTK1500 | 1115 | 1480 | 323 | 760 | 12 | 1 |

| PTK1800 | 1190 | 1780 | 323 | 910 | 12 | 2 |

| PTK2350 | 1595 | 2330 | 406 | 1150 | 16 | 2 |

| PTK2500 | 1720 | 2480 | 406 | 1290 | 16 | 2 |

| PTK2600 | 1820 | 2580 | 406 | 1350 | 16 | 2 |

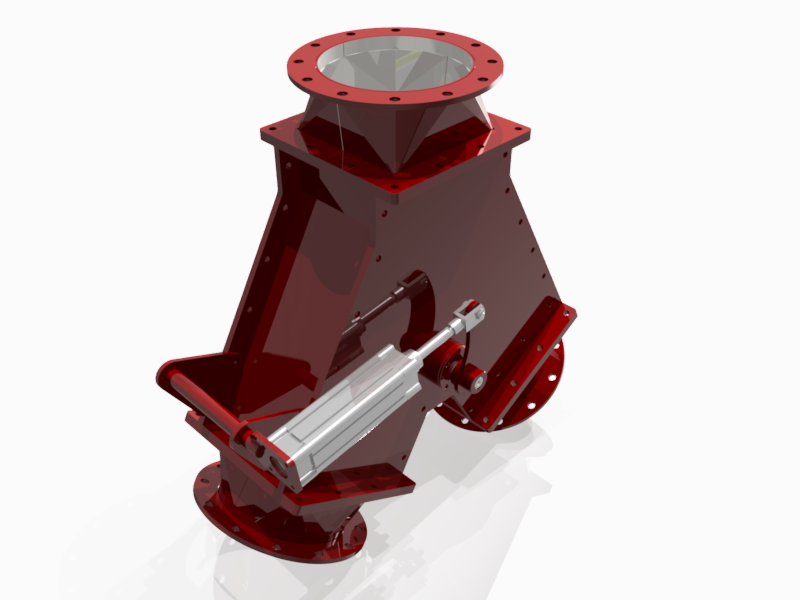

Numerous industries such as the mining industry, minerals industry and the cement industry handle bulk materials that tend to be abrasive. Such materials are quite harsh they have a higher wearing effect than other materials. This wearing effect has a great impact on the life span of the equipment used to handle materials possessing the aforementioned nature. For this reason, these devices have to be manufactured from wear-resistant materials.

Numerous industries such as the mining industry, minerals industry and the cement industry handle bulk materials that tend to be abrasive. Such materials are quite harsh they have a higher wearing effect than other materials. This wearing effect has a great impact on the life span of the equipment used to handle materials possessing the aforementioned nature. For this reason, these devices have to be manufactured from wear-resistant materials.

Polimak manufactures bin activators that are specifically suitable for handling materials that are abrasive. Our wear-resistant bin activators are constructed from hardox making them robust and durable. They reduce the effects of wear, thus promoting efficiency and productivity.

Features

- Construction Material: Hardox.

- 1 or 2 electric motors (vibrators).

- 4 to 16 suspensions.

- Single outlet.

- Flexible connector sleeve

- Primary baffle plate

- Inlet skirt

- Multiple outlets (optional)

- Secondary baffle plate (optional)

Benefits

- A wear-resistant surface.

- Prolonged usable life span of the polyurethane connector sleeve.

- Smooth and continuous bulk solid flow assurance.

- Ratholing, bridging and segregation prevention.

- Prevention of material spillage thereby reduced product loss.

- Downtime reduction, thus promoting productivity.

Bin Activator Dimensions Table

| MODEL | A(mm) | ØDI (mm) | ØDO (mm) | H (mm) | No. of Suspensions | No. of Motors |

| PTK600 | 500 | 580 | 168 | 400 | 4 | 1 |

| PTK900 | 685 | 880 | 219 | 520 | 4 | 1 |

| PTK1500 | 1115 | 1480 | 323 | 760 | 12 | 1 |

| PTK1800 | 1190 | 1780 | 323 | 910 | 12 | 2 |

| PTK2350 | 1595 | 2330 | 406 | 1150 | 16 | 2 |

| PTK2500 | 1720 | 2480 | 406 | 1290 | 16 | 2 |

| PTK2600 | 1820 | 2580 | 406 | 1350 | 16 | 2 |

Polimak offers a variety of bin activators with innovative options and accessories. These accessories and options ensure optimized operations as well as safety over time.

Secondary Baffle Plate

The secondary baffle plate also referred to as a secondary deflector, helps prevent the jamming and compacting of bulk materials at the outlet, thus allowing smooth material through the outlet of the bin activator.

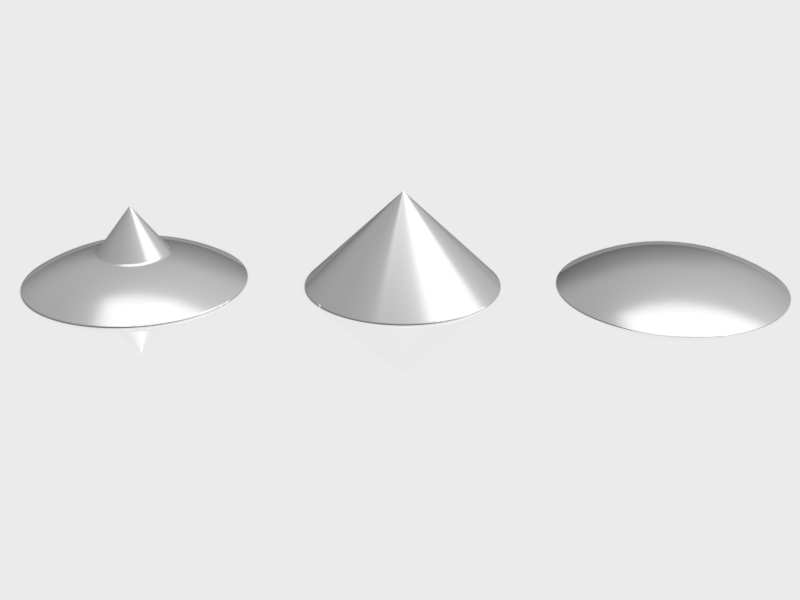

Internal Baffle

Different internal baffle designs can be integrated into the design of bin activators depending on the application and handled material. The different deflector plate designs are conical deflector plates with varying slant angles – 15°, 30°, 45° and 60°, convex deflector plates and compound deflector plates.

Multiple Outlets

Multiple bin activator outlets promote material flow from a single source feeding vessel to multiple receiving units. Multiple outlets design eliminate the demand for using diverter valves.

Sleeve Seal

Polyurethane sleeve seals are commonly used in most applications to create a flexible seal between the activator cone and the upstream device. Polimak offers a silicone or rubber sleeve seals depending on the application and handling material.

Diverter Valve

A flap type diverter valve is commonly used with a single outlet bin activator to redirect the flow of dry bulk materials to different receiving units, one at a time. The hinged flap is responsible for rerouting the material flow.

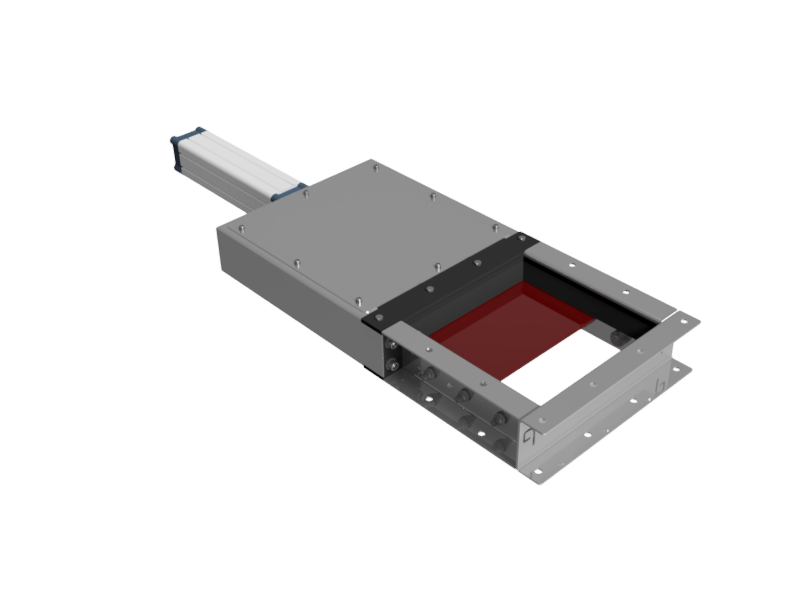

Slide Gate Valve

A slide gate valve is used to open or shut off the flow of bulk materials from a bin activator. Depending on the design type, a slide gate valve can be operated manually or automatically. A slide gate valve can be installed to the outlet of a single outlet bin activator.

Butterfly Valve

A butterfly valve is used to offer efficient flow control of free-flowing bulk materials with the help of a rotating disc. The rotation disc inside the housing of the valve rotates up to 90 degrees. A butterfly valve is typically installed to the outlet of a single outlet bin activator.

Vibration Sensor

A vibration sensor comes in handy because, with it, the vibrations of an electric motor can be easily detected. Whenever abnormal frequencies are detected, an operator is notified and necessary measures can be carried out.